News

Unlock Precision with Best Slitter Blades and Food Blades

In industries that rely on precision cutting, the right tools make all the difference. Whether you're working with materials in manufacturing or processing food, slitter blades and food blades play a crucial role in ensuring efficiency, quality, and safety. These cutting tools are indispensable for businesses aiming to maintain high productivity and consistent output. Let’s explore the unique benefits of both slitter blades and food blades, and how investing in high-quality blades can elevate your operations.

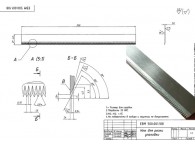

Advantages of Slitter Blades

Slitter blades are essential for industries that work with paper, plastics, textiles, and metals. These blades are designed for precision cutting, ensuring clean and accurate slits on various materials. Here’s why they are so valuable to manufacturers:Superior Cutting Precision

The primary advantage of slitter blades is their ability to deliver clean, sharp cuts on a wide range of materials. Whether it's thin film or thick metal sheets, these blades offer unmatched precision, reducing waste and ensuring product consistency.

Increased Efficiency

High-quality slitter blades enhance production efficiency by reducing downtime. Their sharpness and durability mean they can cut for longer periods without needing frequent sharpening or replacement, minimizing interruptions in the production process.

Cost-Effective

While investing in premium slitter blades might seem like a higher upfront cost, their long-lasting performance makes them a cost-effective solution in the long run. They minimize material waste and reduce the frequency of blade changes, leading to lower maintenance costs and higher productivity.

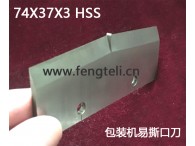

Versatility Across Industries

From packaging materials to aluminum sheets, slitter blades are used across multiple industries. Their versatility makes them an indispensable tool for any business looking to cut a variety of materials with precision and speed.

Enhancing Food Processing with Food Blades

When it comes to food processing, ensuring safety and precision is paramount. Food blades are specifically designed to handle various tasks such as slicing, dicing, and portioning food products while maintaining hygiene and safety standards. These blades are vital for businesses involved in food production, whether large-scale or artisanal.Hygienic and Food-Safe

Food blades are made from food-grade stainless steel, ensuring that they meet the stringent hygiene standards required in the food industry. They resist corrosion and contamination, making them ideal for cutting raw meats, vegetables, and other food products.

Precise Cuts for Better Presentation

Precision is key in food preparation, especially when aesthetics matter. Food blades offer sharp, consistent cuts, ensuring that food products maintain their shape and texture. This is crucial in industries where food presentation can impact the perceived value of the product.

Durability and Longevity

Designed to withstand constant use, food blades are highly durable. Their corrosion-resistant materials ensure longevity, even in environments that involve moisture and high acidity. This durability leads to reduced costs in blade replacement and ensures consistent performance over time.

Customizable for Specific Needs

Just like slitter blades, food blades can be customized for specific applications. Whether you need a blade for high-speed slicing or for precision cuts in delicate food products, you can find a food blade tailored to your unique needs. Customization allows for improved efficiency and better results in food processing operations.

Maximize Performance with the Right Blades

Both slitter blades and food blades offer distinct advantages in their respective industries. For businesses in manufacturing and food processing, using high-quality blades tailored to your needs can lead to better product quality, reduced waste, and increased operational efficiency. Here’s why choosing the right blades matters:- Long-Lasting Performance: Investing in durable blades reduces the need for frequent replacements, saving on costs and improving productivity.

- Precision and Clean Cuts: Clean cuts result in less material waste and better product presentation, whether you’re dealing with packaging materials or food products.

- Customization: Both types of blades can be customized for specific tasks, ensuring that you get the best results for your unique operations.