News

Precision in Every Slice: The Indispensable World of Food Blades

Imagine the seamless efficiency of a large-scale food processing plant, where thousands of products are sliced, diced, and prepared with unwavering consistency. At the heart of this precision are specialized tools designed for the unique demands of the food industry: food blades. These aren't just any cutting edges; they are meticulously engineered instruments critical for safety, hygiene, and product quality. For businesses in China and worldwide seeking superior cutting solutions, FTL Knives stands as a beacon of excellence, providing blades that meet the highest standards.

The Critical Role of Food Blades in Processing

Food blades are integral to every stage of food production, from raw ingredient preparation to final packaging. Unlike general-purpose blades, those used in food processing must adhere to incredibly strict standards for material composition, sharpness, durability, and most importantly, food safety. They are designed to cut through diverse textures – from delicate meats and vegetables to frozen goods and baked products – with minimal material loss and maximum efficiency. The right food blade can significantly reduce processing time, minimize waste, and maintain the integrity and appearance of the food product.

The Demands of Food Processing: Precision, Hygiene, Durability

The environment of a food processing facility is demanding. Food blades must withstand:-Corrosion: Constant exposure to moisture, acids, and cleaning agents necessitates highly corrosion-resistant materials.

-Wear: Continuous use requires exceptional hardness and edge retention to maintain sharpness.

-Hygiene: Blades must be easy to clean and sanitize, often made from food-grade stainless steel to prevent bacterial growth and cross-contamination.

-Precision: Consistent cuts are vital for product uniformity, portion control, and aesthetic appeal.

-Safety: Blades must be designed to minimize risks during operation and maintenance.

FTL Knives: Your Expert in Food Processing Blades

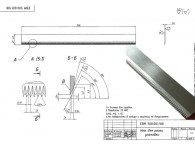

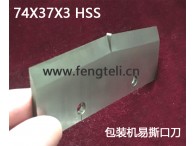

As a specialized manufacturer of industrial knives in China, FTL Knives has honed its expertise in producing premium food blades that meet the rigorous demands of the food processing industry. We utilize only high-grade, food-safe stainless steel and advanced manufacturing techniques, including precision grinding and heat treatment, to ensure our blades offer superior sharpness, unparalleled durability, and excellent corrosion resistance. Our extensive product range includes blades for slicing, dicing, mincing, portioning, and deboning, catering to various types of food products and processing machinery. FTL Knives is committed to innovation, continually improving our designs and materials to provide optimal cutting solutions.

The FTL Knives Advantage: Performance and Customization

Choosing FTL Knives as your food blades supplier means choosing a partner dedicated to optimizing your food processing operations. We offer:-Exceptional Sharpness & Edge Retention: Our blades deliver clean, precise cuts, reducing product waste and improving output.

-Superior Durability: Engineered for extended lifespan, minimizing downtime and replacement costs.

-Hygienic Design: Easy to clean and sanitize, adhering to the strictest food safety regulations.

-Custom Solutions: We understand that every processing line is unique. FTL Knives offers custom fabrication services to design and manufacture blades precisely tailored to your specific machinery and cutting requirements.

-Reliable Service: With efficient production and robust supply chain, we ensure timely delivery to clients in China and globally.

FAQs about Food Blades and FTL Knives

Q1: What materials are FTL Knives' food blades made from to ensure hygiene? A1: FTL Knives uses high-grade, food-safe stainless steel for its food blades, which are highly resistant to corrosion and designed for easy cleaning and sanitization to meet hygiene standards.Q2: Can FTL Knives provide blades for various types of food processing machinery? A2: Yes, FTL Knives manufactures a wide array of food blades designed for compatibility with various food processing machinery, including slicers, dicers, grinders, and more.

Q3: How often should food blades be sharpened or replaced? A3: The frequency of sharpening or replacement for food blades depends on usage, material being cut, and blade type. FTL Knives blades are designed for extended life, but regular inspection is recommended.

Q4: Does FTL Knives offer custom-designed food blades? A4: Absolutely. FTL Knives specializes in providing custom food blades tailored to specific dimensions, materials, and cutting needs of individual clients and unique food processing applications.

Q5: What is the benefit of using high-quality food blades in terms of product quality? A5: High-quality food blades from FTL Knives ensure clean, consistent cuts, reducing damage to food products, maintaining their freshness, appearance, and overall quality, which is crucial for consumer satisfaction.

Conclusion

For the food processing industry in China and worldwide, precision, hygiene, and efficiency are non-negotiable. FTL Knives delivers on all fronts with its superior food blades, ensuring your operations run smoothly and your products maintain their integrity.