News

Precision in Every Cut: The Essential Role of Food Blades

In the fast-paced and hygiene-critical environment of the food industry, precision, efficiency, and safety are paramount. From slicing deli meats and dicing vegetables to processing baked goods and preparing specialty foods, the quality of the cutting tools directly impacts product consistency, waste reduction, and operational speed. This is where specialized Food Blades become indispensable. At FTLKNIVES, we understand the rigorous demands of food processing and are dedicated to manufacturing high-performance food blades that deliver superior cutting results and uphold the highest standards of hygiene.

More Than Just a Knife: What are Food Blades?

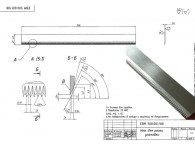

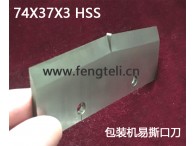

Food blades are precision cutting tools specifically designed for use in various stages of food processing. Unlike general-purpose blades, food blades are engineered from food-grade materials (typically high-grade stainless steel or specialized alloys) that are corrosion-resistant, easy to clean, and comply with strict food safety regulations. They come in an enormous variety of shapes, sizes, and edge geometries – from circular slitting blades and straight slicing knives to jagged bread blades and intricate dicing blades – each optimized for specific food types and processing tasks. Their design minimizes product adhesion, reduces friction, and ensures clean, precise cuts every time.

FTLKNIVES: Crafting Precision for the Food Industry

As a specialized manufacturer of industrial knives, FTLKNIVES prides itself on producing a comprehensive range of high-quality food blades that meet the stringent demands of the food processing industry. We utilize advanced materials, precision grinding techniques, and strict quality control to ensure our blades offer exceptional sharpness, extended edge retention, and superior corrosion resistance. Our expertise extends to custom blade manufacturing, allowing us to design and produce food blades that perfectly fit your specific machinery and processing requirements, optimizing your production lines for efficiency and product quality. Our commitment to excellence makes us a trusted name for industrial cutting solutions in China.

The Impact of High-Quality Food Blades on Your Operations

Investing in superior food blades offers a wealth of benefits for food processing businesses:-Enhanced Product Quality: Clean, consistent cuts improve the appearance, texture, and portion control of food products.

-Increased Efficiency: Sharper, more durable blades reduce downtime for replacements and sharpening, boosting throughput.

-Reduced Waste: Precise cutting minimizes material loss and rejects, leading to higher yield.

-Improved Hygiene & Safety: Food-grade materials and easy-to-clean designs prevent bacterial buildup, while consistent performance reduces the risk of accidents.

-Cost Savings: Longer blade life and fewer replacements translate to significant long-term operational cost reductions.

-Versatility: Specific blade designs optimize cutting for different food types, from frozen meats to delicate pastries.

FTLKNIVES: Your Partner in Food Processing Excellence

At FTLKNIVES, our dedication goes beyond just manufacturing. We work closely with our clients to understand their unique processing challenges and provide expert advice on selecting the ideal food blades for their machinery and applications. Our team is committed to delivering not only superior products but also exceptional service, ensuring that your food processing operations run smoothly, efficiently, and safely. We are your reliable partner for achieving precision in every cut.

FAQs About Food Blades

Q1: What materials are typically used for food blades?oA1: Food blades are primarily made from high-grade stainless steels (e.g., 420, 440C, or specialized alloys) for their corrosion resistance, hardness, and ability to hold a sharp edge, all while meeting food safety standards.

Q2: How often should food blades be sharpened or replaced?

oA2: The frequency depends on the material being cut, usage volume, and blade material. Regular inspection is key. Sharp blades reduce wear on machinery and improve product quality, so timely sharpening or replacement is crucial.

Q3: Are all food blades compatible with any food processing machine?

oA3: No, food blades are typically specific to the make and model of the food processing machine. Dimensions, mounting holes, and edge profiles must match precisely. Custom solutions are often required.

Q4: What is the importance of hygiene for food blades?

oA4: Hygiene is paramount to prevent cross-contamination and bacterial growth. Food blades must be easily cleanable, corrosion-resistant, and free from crevices where food particles can accumulate.

Q5: Can food blades be designed for specific cutting tasks?

oA5: Absolutely. FTLKNIVES specializes in custom food blade manufacturing, designing unique edge geometries, tooth patterns, and blade shapes to optimize cutting for specific food products or processing requirements.

Achieve Culinary Precision with FTLKNIVES!

For unparalleled cutting performance, hygiene, and durability in your food processing operations, choose the precision of Food Blades from FTLKNIVES. Contact us today to explore our extensive range of high-quality industrial knives and discover how we can help you achieve perfection in every cut.