News

Innovative Food Blades: Top Manufacturers, Trends

Views: 368 Update Date: Mar 04 , 2025

Introduction: The Critical Role of Food Blades in Modern Industry

Introduction: The Critical Role of Food Blades in Modern Industry

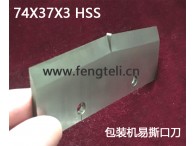

Food blades are the unsung heroes of the global food processing sector, enabling everything from vegetable dicing to meat slicing with surgical precision. As consumer demand for ready-to-eat meals, plant-based proteins, and uniform packaging surges, the need for high-performance blades has never been greater. This article examines cutting-edge trends, material breakthroughs, and why FengTeLi Machine Blade stands out as China's premier supplier of industrial food blades.Industry Trends Driving Food Blade Innovation

1. Demand for High-Speed, Low-Waste Processing- Automated Lines: Food manufacturers require blades that withstand 24/7 operation in robotic systems (e.g., IQF vegetable cutters).

- Sustainability: Blades with ultra-sharp edges reduce food waste by 15% through cleaner cuts, aligning with ESG goals.

2. Diverse Material Requirements

- Stainless Steel Dominance: 440C and VG-10 steel blades dominate for corrosion resistance and edge retention.

- Ceramic Blades: Gaining traction in gluten-free and allergen-free production lines to prevent cross-contamination.

3. Customization for Niche Applications

- Meat Alternatives: Blades tailored for plant-based protein textures (e.g., mycoprotein or pea protein).

- Frozen Food Boom: Cryogenic-treated blades that resist brittleness at -40°C.

FengTeLi Machine Blade: China's Leader in Food Blade Technology

With over 20 years of expertise,has become synonymous with reliability and innovation. Here's why global giants like Nestlé and Tyson Foods trust their solutions:1. Advanced Manufacturing Capabilities

- Laser Cutting & Cryo-Quenching: Ensures micron-level precision and extended blade lifespan (2–3x industry average).

- Custom Geometry: Tailored blade designs for specific tasks, such as wave-edged blades for tear-free herb cutting or serrated blades for frozen meat.

2. Certifications & Compliance

- ISO 22000: Meets food safety management standards for direct food contact.

- FDA & EU Compliance: Materials approved for global export.

3. Sustainability Initiatives

- Recyclable Blades: 90% of stainless steel components are recyclable.

- Energy-Efficient Production: Solar-powered factories in Jiangsu reduce carbon footprint by 40%.

4. Global Support Network

- 24/7 Technical Assistance: Remote diagnostics and on-site sharpening services across Asia, Europe, and North America.

- Case Study: A Thai seafood processor reduced downtime by 30% after switching to FengTeLi's anti-corrosion titanium-coated blades.

How to Choose the Right Food Blades Supplier

How to Choose the Right Food Blades Supplier

1. Material Compatibility- Verify blade hardness (HRC 58–62 for most applications) and corrosion resistance.

- Request material test reports (MTRs) for traceability.

2. Customization Flexibility

- Suppliers should offer CAD-based design adjustments for unique production lines.

3. Total Cost of Ownership (TCO)

- Factor in sharpening intervals, replacement cycles, and energy efficiency.

4. Industry Reputation

- Check certifications and client testimonials (e.g., FengTeLi's partnerships with JBS S.A. and Unilever).

Future Outlook: Smart Food Blades and AI Integration

- IoT-Enabled Blades: Sensors to monitor wear and predict failure, integrated with factory ERP systems.- Self-Sharpening Coatings: Nano-ceramic layers that regenerate edges during operation (prototypes expected by 2027).

Conclusion: Precision Meets Sustainability with FengTeLi Food Blades

For food processors aiming to optimize efficiency, reduce waste, and meet stringent safety standards,delivers unparalleled expertise. Their fusion of traditional craftsmanship and modern technology positions them as the go-to partner for tomorrow's food industry challenges.Explore FengTeLi's Food Blades Solutions: Visit http://www.ftlknives.com/ for product catalogs, case studies, and a free blade consultation.