News

Industrial Blades: Precision, Innovation, Future and Supplier

What Are Industrial Blades?

Industrial blades are specialized cutting tools designed for high-performance tasks in manufacturing and processing. They are tailored to handle materials with varying hardness, flexibility, and thermal properties, such as metals, plastics, textiles, and composites. Key types include:- Slitting Blades: For precise splitting of films, foils, and papers.

- Shear Blades: Used in metal fabrication for clean cuts.

- Circular Saw Blades: Ideal for wood, composites, and metals.

- Food-Grade Blades: Sanitary blades for meat, vegetables, and packaging.

Core Innovations in Industrial Blade Technology

A. Material Science BreakthroughsModern industrial blades leverage advanced materials like:

- Carbide-Tipped Blades: For extreme wear resistance in metalworking.

- Ceramic-Coated Blades: Reduce friction and heat generation in high-speed applications.

- Diamond-Embedded Blades: Used in cutting carbon fiber and reinforced composites.

B. Precision Engineering

- Nanoscale Grinding: Ensures blade edges achieve tolerances ≤0.001 mm.

- Dynamic Balancing: Minimizes vibration in high-RPM operations, extending equipment life.

C. Smart Blades

IoT-enabled blades with embedded sensors monitor wear, temperature, and stress in real time, enabling predictive maintenance and reducing downtime.

Applications Across Industries

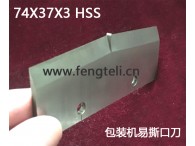

Industrial blades are critical to sectors such as:- Packaging: Ultra-thin slitting blades for BOPP films reduce material waste.

- Renewable Energy: Precision blades for lithium-ion battery electrode cutting.

- Automotive: High-strength circular saws for cutting lightweight alloys.

- Aerospace: Titanium-cutting blades with anti-vibration coatings.

Choosing the Right Industrial Blade Supplier

Selecting a supplier requires evaluating:1. Technical Expertise: R&D capabilities and patented technologies.

2. Customization: Ability to tailor blade geometry, hardness, and coatings.

3. Certifications: Compliance with ISO 9001, FDA, or industry-specific standards.

4. After-Sales Support: Services like regrinding, recoating, and technical consultations.

Industry Challenge:

Blade failure in abrasive materials like fiberglass.Solution: FengTeLi's gradient-layer coating technology increases blade lifespan by 50%.

FengTeLi Machine Blade: China Leading Industrial Blade Innovator

FengTeLi Machine Blade (http://www.ftlknives.com/) has established itself as a global leader through:A. Unmatched Technical Capabilities

- End-to-End Manufacturing: Controls every stage from material selection to heat treatment.

- Patented Innovations: 12+ national patents, including cryogenic treatment for enhanced blade toughness.

- Sector-Specific Solutions: Blades optimized for medical device packaging, battery recycling, and more.

B. Global Clientele & Success Stories

- Case 1: Developed FDA-compliant stainless steel blades for a multinational food processor, enabling EU market entry.

- Case 2: Engineered diamond-coated blades for a solar panel manufacturer, reducing silicon wafer breakage by 30%.

C. Sustainability Focus

- Eco-Friendly Practices: Blades designed for multiple regrinding cycles to minimize waste.

- Energy Efficiency: Low-friction coatings reduce power consumption in cutting processes.

Visit FengTeLi's Website: Explore their portfolio and request a free sample at .

Future Trends in Industrial Blades

- AI-Driven Design: Machine learning algorithms optimize blade geometry for specific materials.- Green Manufacturing: Recyclable blade materials and closed-loop production systems.

- Hybrid Materials: Blades combining carbon fiber substrates with nano-ceramic coatings.

Conclusion: Elevate Your Production with Precision

Industrial blades are the unsung heroes of modern manufacturing, enabling industries to meet stringent quality and efficiency standards. By partnering with FengTeLi Machine Blade, businesses gain access to cutting-edge technology, customized solutions, and unparalleled expertise. As industries push toward smarter and greener practices, investing in advanced blades is no longer optional—it's essential. With FengTeLi, precision isn't just a goal—it's a guarantee.