News

Everything You Need to Know About Slitter Blades

Slitter blades are essential components in various industries that require precise cutting of materials. These blades play a key role in converting and manufacturing processes where materials like paper, metal, plastic, and rubber need to be cut into narrower strips or sheets. Whether you’re in the packaging, printing, or metalworking industry, understanding the importance and functionality of slitter blades can help ensure optimal performance and productivity in your operations.

Slitter blades are essential components in various industries that require precise cutting of materials. These blades play a key role in converting and manufacturing processes where materials like paper, metal, plastic, and rubber need to be cut into narrower strips or sheets. Whether you’re in the packaging, printing, or metalworking industry, understanding the importance and functionality of slitter blades can help ensure optimal performance and productivity in your operations.

What Are Slitter Blades?

Slitter blades are specialized cutting tools used in slitting machines to cut wide rolls of material into narrower strips. These blades are typically made from high-quality tool steel or carbide to withstand the stresses of high-speed cutting and provide long-lasting performance. They come in various sizes, shapes, and designs, depending on the material being cut and the specific requirements of the slitting process.The slitting process involves the use of rotary slitter blades that rotate against each other or against a stationary anvil, slicing through the material. The cuts made by slitter blades are clean, precise, and consistent, which is essential for industries where the material’s integrity and quality are paramount.

Applications of Slitter Blades

Slitter blades are used in many industries where material conversion and precision cutting are essential. Some of the key applications include:●Paper and Packaging Industry: Slitter blades are used to cut large rolls of paper or cardboard into smaller, more manageable sheets or strips for packaging applications.

●Metalworking: In the metal industry, slitter blades are employed to cut metal coils into narrower strips or sheets, which are then used for further manufacturing processes.

●Printing Industry: Slitter blades help convert printed rolls of paper into precise sheet sizes or cut specific designs into packaging materials.

●Textile Industry: Slitter blades are used to cut fabric rolls into strips, enabling the production of various textile products.

●Plastic and Rubber Industry: Slitter blades are also used to cut wide rolls of plastic or rubber into narrower strips, used in manufacturing or packaging.

Types of Slitter Blades

Slitter blades come in a variety of designs, each suited to a specific cutting task. Some common types include:●Round Slitter Blades: These are the most common type of slitter blades used for cutting a variety of materials. They are circular in shape and used in rotary slitting machines.

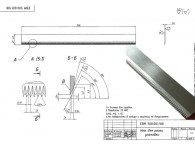

●Hollow Ground Slitter Blades: These blades are ground with a concave shape, ensuring that they maintain sharpness for longer periods and provide cleaner cuts.

●Shear Slitter Blades: These blades use a shear-type cutting action and are typically used for cutting materials like paper and plastic.

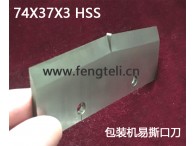

●Straight Slitter Blades: These blades are used for precision cutting where a straight cut is required. They are often used for cutting metals and other rigid materials.

Material and Coatings of Slitter Blades

The material of slitter blades is a key factor in determining their longevity and cutting performance. Common materials used in the production of slitter blades include:●High-Speed Steel (HSS): HSS blades offer excellent durability and performance, especially in high-speed cutting applications.

●Carbide: Carbide slitter blades are extremely durable and resistant to wear, making them ideal for cutting hard or abrasive materials.

●Tool Steel: Tool steel is commonly used for slitter blades due to its hardness, strength, and resistance to wear.

Coatings can also play a significant role in enhancing the performance of slitter blades. Coatings like titanium nitride (TiN) or carbide coatings help reduce friction, extend blade life, and ensure smoother cuts.

Choosing the Right Slitter Blade

Selecting the right slitter blade for your specific application depends on several factors:1.Material Type: Different materials require different types of blades. For example, cutting metal may require a carbide-coated blade, while cutting paper may call for a high-speed steel blade.

2.Blade Sharpness and Durability: A blade that stays sharp for a longer period will reduce downtime and improve productivity. Consider the hardness and coating of the blade.

3.Cutting Speed: High-speed cutting requires blades that can withstand the heat and pressure of continuous operation. Choose blades that can handle high speeds without losing their sharpness or effectiveness.

4.Cut Quality: The quality of the cut is critical, especially in industries like packaging or printing. A sharp, high-quality blade will produce clean and precise cuts, minimizing waste and defects.

Maintenance and Care of Slitter Blades

Proper maintenance and care of slitter blades are essential to ensuring their longevity and performance. Regularly inspect the blades for signs of wear or damage, and replace them as needed to maintain cutting precision. Blade sharpening is another key part of maintenance. Dull blades can cause jagged cuts, leading to material wastage and increased downtime.

Conclusion

Slitter blades are a vital tool in many industrial and manufacturing processes, offering precise and efficient cutting of various materials. Whether you're working with paper, metal, plastic, or rubber, choosing the right slitter blade is crucial for maximizing productivity and ensuring high-quality results. By understanding the different types of blades, materials, and coatings available, you can make informed decisions that contribute to the success of your operations.