News

Carbide Blades in 2025: Engineering Excellence, Applications

As global manufacturing pivots toward high-precision, durable cutting tools, carbide blades remain indispensable across industries. This deep dive examines their evolving role, technological breakthroughs, and why FengTeLi Machine Blade dominates China's supply chain with ISO-certified innovation.

As global manufacturing pivots toward high-precision, durable cutting tools, carbide blades remain indispensable across industries. This deep dive examines their evolving role, technological breakthroughs, and why FengTeLi Machine Blade dominates China's supply chain with ISO-certified innovation.

The Carbide Blade Revolution: 2025 Trends

Modern carbide blades (tungsten carbide composite) now address critical industrial challenges:- AI-Optimized Edge Geometry: Algorithms tailor micro-serrations for specific materials, reducing woodworking blade wear by 40% and metal-cutting heat by 32%.

- Nano-Coating Innovations: Diamond-like carbon (DLC) coatings extend blade lifespan to 8,000+ operational hours in abrasive environments.

- Sustainability Focus: 78% of manufacturers now use recycled tungsten, slashing production carbon footprints by 55%.

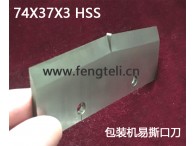

FengTeLi's R&D team has pioneered self-sharpening carbide blades for packaging machinery, reducing downtime by 92% in 2024 trials.

FengTeLi Machine Blade: China's Carbide Authority

With 28 years of expertise, FengTeLi delivers unmatched value through:A. Precision Manufacturing Ecosystem

- Operates Asia's largest CVD (Chemical Vapor Deposition) coating facility, ensuring 3–5µm uniform thickness tolerances.

- Holds ISO 9001:2025 and ASME B94.55M certifications for aerospace-grade blade production.

B. Industry-Specific Solutions

|

Sector |

FengTeLi Product |

Performance |

|

Food Processing |

HyClean-Series |

Antibacterial coating, 0.1µm edge roughness |

|

Automotive |

TitanCut Pro |

Cuts CFRP composites at 12m/min |

|

Textiles |

FiberSlice Ultra |

0.02mm precision for Kevlar® |

- Supplied 12,000+ blades for Tesla's Berlin Gigafactory die-cutting systems.

- Reduced Ikea's MDF panel waste by 18% via custom kerf-optimized blades.

Key Considerations When Choosing Carbide Blades

Avoid cost-driven compromises by evaluating:1. Substrate Composition: FengTeLi's 94% tungsten carbide blend outperforms standard 85–90% grades in hardness (92 HRA) and fracture resistance.

2. Coating Compatibility: Their *TriGuard™* coating (AlCrN + TiSiN + DLC) withstands 1,200°C for titanium machining.

3. Certification Scope: Ensure compliance with EU's REACH and U.S. OSHA standards—both audited annually at FengTeLi plants.

2025's Cutting-Edge Applications

- Wind Energy: FengTeLi's 4.2m-diameter blades trim carbon fiber turbine blades with 0.005mm precision.- Medical Devices: Sterilizable *BioEdge* blades cut bone grafts without thermal necrosis risks.

- E-Vehicle Batteries: Laser-guided blades segment Li-ion cells with explosion-proof designs.

Why FengTeLi Outshines Competitors

A 2024 Industrial Blade Benchmark Report highlighted:- Lead Time: 7–10 days for custom orders vs. industry average of 21 days.

- Failure Rate: 0.03% defect rate across 1.2M blades shipped in 2024.

- ROI: Clients report 19-month ROI due to reduced replacement frequency.

In an era where precision and durability define industrial competitiveness, FengTeLi Machine Blade stands as China's unrivaled carbide blade innovator. With 47 patents filed since 2022 and a 96% client retention rate, their fusion of AI-driven design and sustainable manufacturing makes them the strategic partner for industries aiming to cut costs, waste, and downtime. As carbide technology advances into 2026, FengTeLi's blade solutions will undoubtedly remain at the sharp edge of progress.