Products

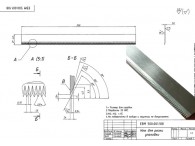

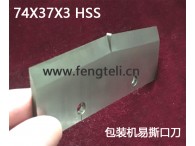

Food Processing Blade

Skinner blades Slicer blades for meat industy

- Product Details

As you can see, the types of blades

and component parts really are not limited by shape or end use – if you can

design it, the odds are pretty good that Fengteli can make it! Fengteli stocks

a wide range of steel types and dimensions, so you can get your parts made in

the alloy you want, on the date you need it. Some of the steels in stock

include A2, M2, D2, 420 DIN, 440, tool steels, 410 Stainless, SKD11, HSS, 310

Stainless, Tungsten Carbide,TC ,insert TC . Don’t see the steel you need? Just

ask – we’ll get it for you.

Basic shapes are formed either

through blanking or laser cutting. A state-of-the-art O2 and N2 laser offers

you tight tolerance cutting, along with tremendous speed and flexibility

processing orders. In addition to our laser cutting capability, you have a

variety of presses available, up to 100 ton capacity, and full die room

capabilities to support your requirements. Our forming capabilities mean you

have the flexibility with one source to handle extremely large order quantities

as well as very small order quantities.

The heat treat/temper department

offers three types of furnaces – both atmosphere and vacuum furnaces as well as

computerized carousel salt bath furnaces – capable of hardening blades up to 64

Rc. Our in-house heat treatment and temper capabilities mean we can process

your parts up to 28″ diameter circular parts and up to 157″ long straight or

shaped parts , and everything in between! Through our extensive experience manufacturing

putty knives, paint scrapers, industrial blades and other tools, Fengteli has

the broadest, most developed and experienced grinding department in the

industry. Whether its surface grinding, Blanchard grinding, or CNC-controlled

multi-axis grinding, you can tap into the capability and experience to put just

about any edge onto your item – beveled, scalloped, toothed serrated, slotted

or whatever your edge requirements may be.

And all of this is supported

with our own millwrights and machinists. In fact, we’ve developed a lot of our

own equipment, as the machines available commercially just couldn’t do what we

wanted them to do!

Steel choice, edge finish style,

bevel angle, edge thickness, surface micro finish, hone technique, flatness,

side run-out… all are critical functions that will affect the performance of

your blade or part in use. With over a century of experience in providing the

right specifications to optimize performance, you know you’ve found a

dependable partner in Fengteli. Tell us what your equipment is designed to cut

and we’ll build you the part you need to accomplish it.